Charles White

Various Robot I have designed

2020 to present / Research and Prototyping Project

Role:

Designer/ Manufacturing/ Programming

Date:

Spring 2020 – Present

A Timeline of designs

Ever since I was a small child the design and idea of the various NASA Mars rovers have fascinated me. When I was very young my parents would bring me to the Denver Museum of Nature and Science. Instead of exploring the interactive exhibits or watching an IMAX documentary, all I wanted to do was watch the animated mission simulation playing next to a full-sized model of the Spirit and Opportunity rovers. I credit this as one of my earliest inspirations that eventually led me to pursue engineering as a degree and career.

When the Covid19 pandemic came around I, like many, found myself with far more time on my hands. My first Co-op at Drexel fell through as it was to start during the first week of lockdown and the company naturally had bigger problems to deal with than bringing in interns. This gave me some time to do some light coursework online from my parent’s house in Colorado, but also gave me an excess of free time. At first, I spent this time working on CAD designs for a theoretical RC car-sized rover design inspired by the Mars rovers that I admired as a child. Then that summer I received a stimulus check in the mail. I used this to purchase my first 3D printer and started printing some of these designs.

As may be expected, these designs did not work very well on my first attempts, but with the time available to me I was able to start rapidly prototyping my ideas. This was naturally excellent practice for CAD and manufacturing that classes would struggle to teach even when they could be in person.

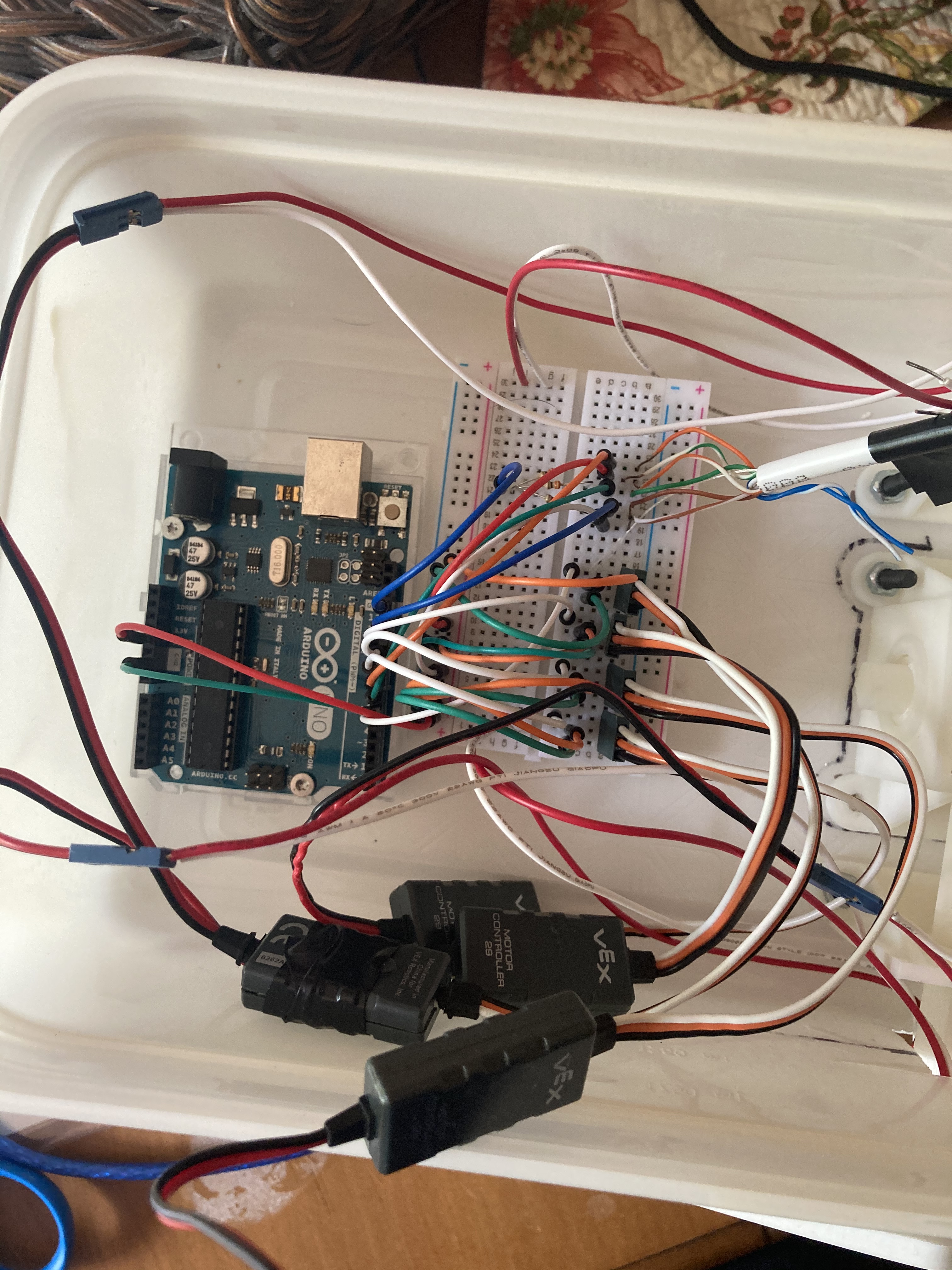

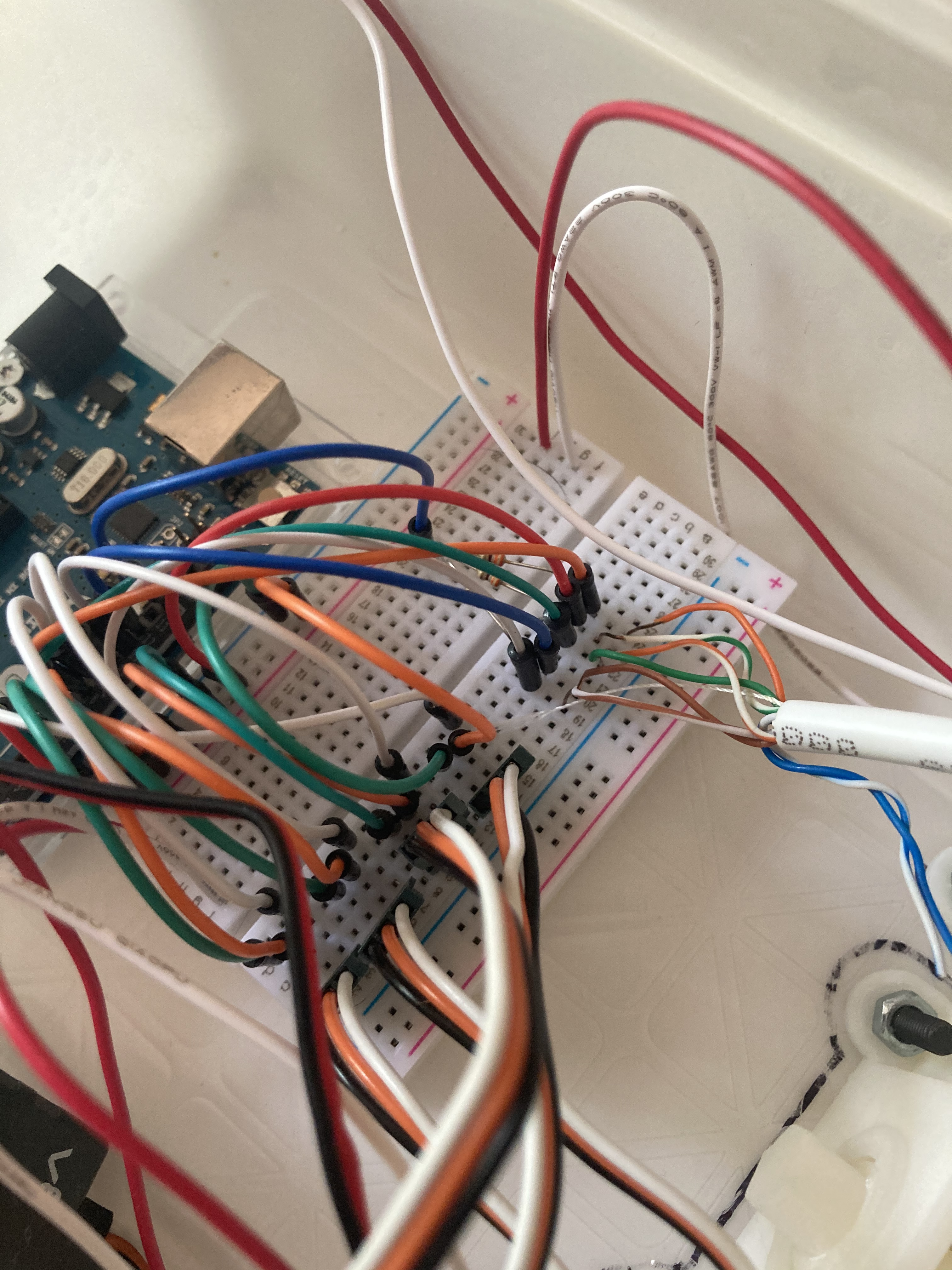

The first version worth mentioning was very simple and basic. The chassis was made from a Tupperware container that I drilled some holes into and stored the electronics inside. The 3D-printed elements were the wheels and suspension system. As the design was inspired by the MER rover design, the suspension system was a “rocker-boogie” design. Due to a severely limited budget, I only had four motor controllers to work with the six wheels on the rover, to remedy this I connected the four outer wheels to two of the motor controllers, and the two inner wheels to the remaining two. To control this rover I used a long ethernet cord with the RJ-45 connectors cut off to directly connect a basic controller to the Arduino that acted as a brain for the rover.

This first prototype taught me that I needed to learn much more about the software and mechanical power transmission processes to make a better rover. After moving back to Philadelphia and needing to leave the first design behind, but not before harvesting the important electronic parts from it, I started working on many new wheel designs. Most of these focused on using less expensive hobby motors as the power plant rather than the more expensive gearbox motors I used earlier. These designs also saw the beginnings of a feedback system to allow me to implement a controls loop for governing the speed at which the wheel would rotate. This is an important feature in making my designs autonomous. None of these designs made it particularly far as I had not taken any controls courses yet, and did not fully understand how I would make a functional control loop. The main issue being a lack of knowledge of what sensors would provide the best data for the loop, and how to write the software for it.

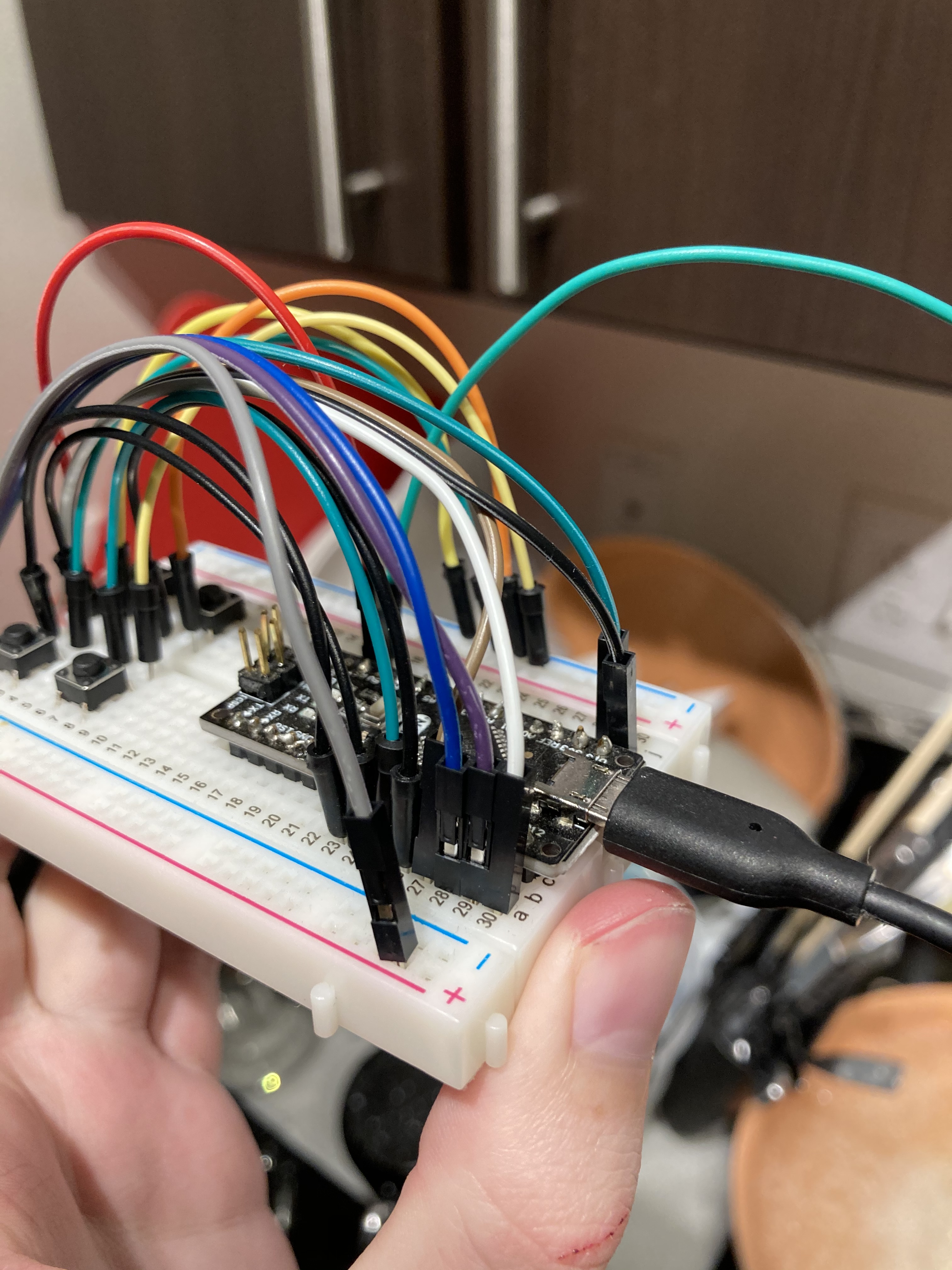

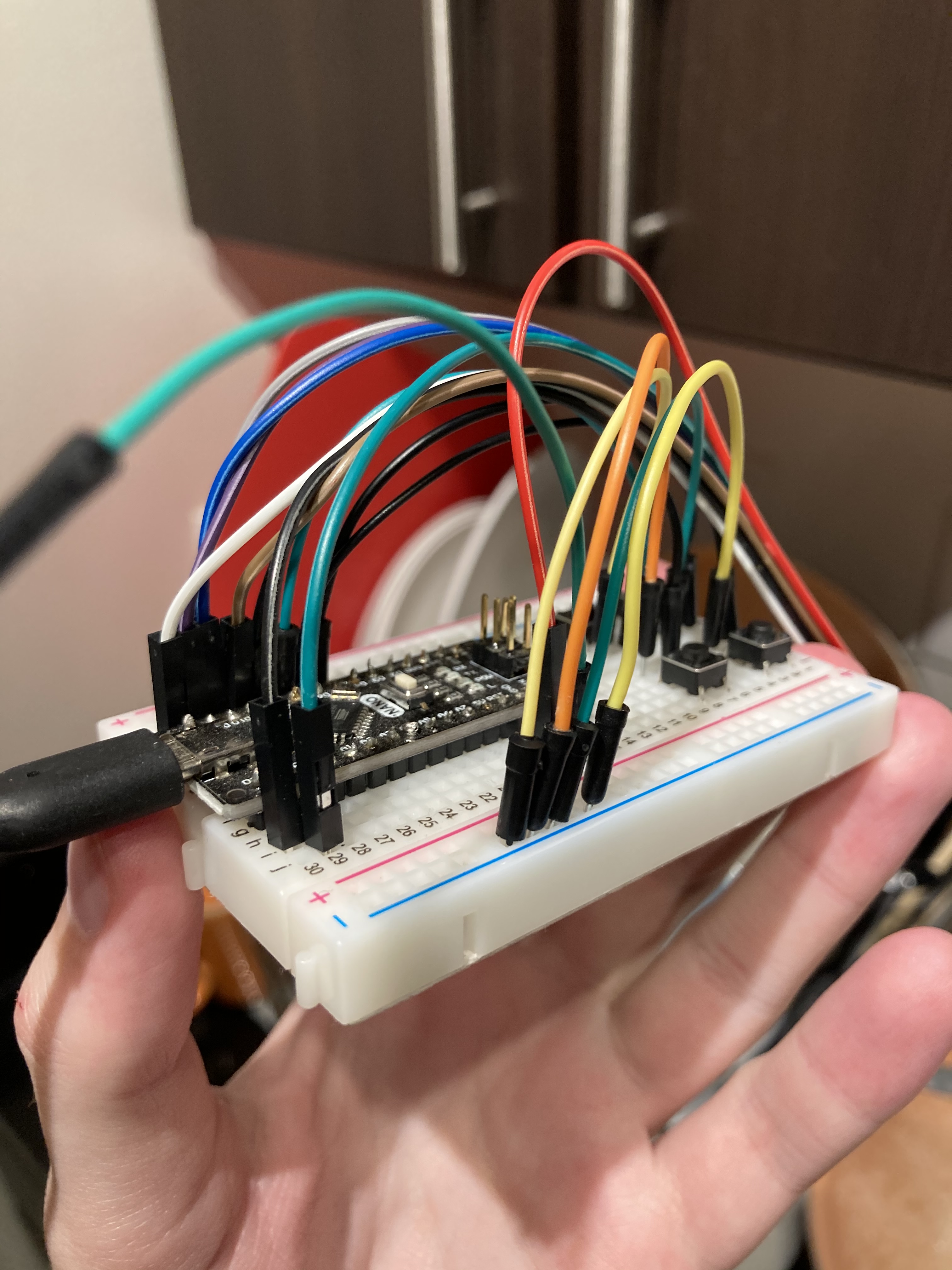

The other problem to tackle was my lack of software knowledge generally. The first rover ran what was a modified servo motor code from an example program that everyone who uses an Arduino has probably seen. A fully autonomous system would need to be far more advanced. One of the early challenges I decided to take on was making the system wireless. To aid my efforts I made a quick robot design based on the basic layout used by my BEST robotics team in high school. This design simply used two large powered wheels for control and an unpowered third wheel or caster for balance. This platform allowed me learn and test wireless communication between Arduinos. While this design was far simpler mechanically, it provided a platform for me to experiment with the software I desperately needed practice with.

The remote was a simple tank drive controller that had a forward and reverse direction for each wheel. This could double as a beacon when attached to my computer to send commands from my laptop instead.

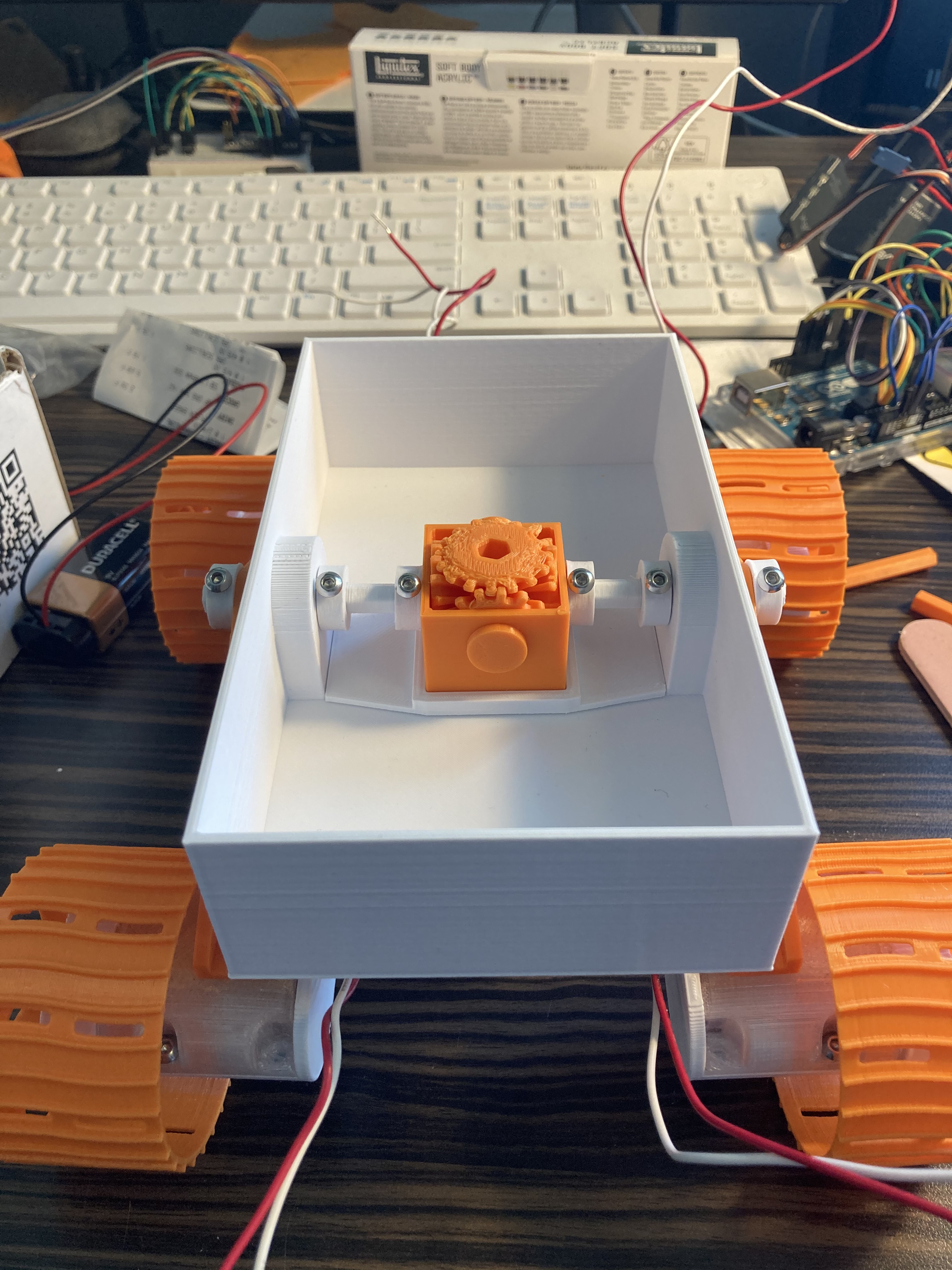

As I researched how to better design my gearboxes for this project I came across the concept of a harmonic gearbox, which I thought had a lot of potential if I could find a way to 3D print one. After some attempts, I made a functional design but found that it was still too stiff to work with the cheap motors I had selected for the project. The use of these motors would continue to cause such problems for some time, but the prototype was made a cool desk ornament in the meantime.

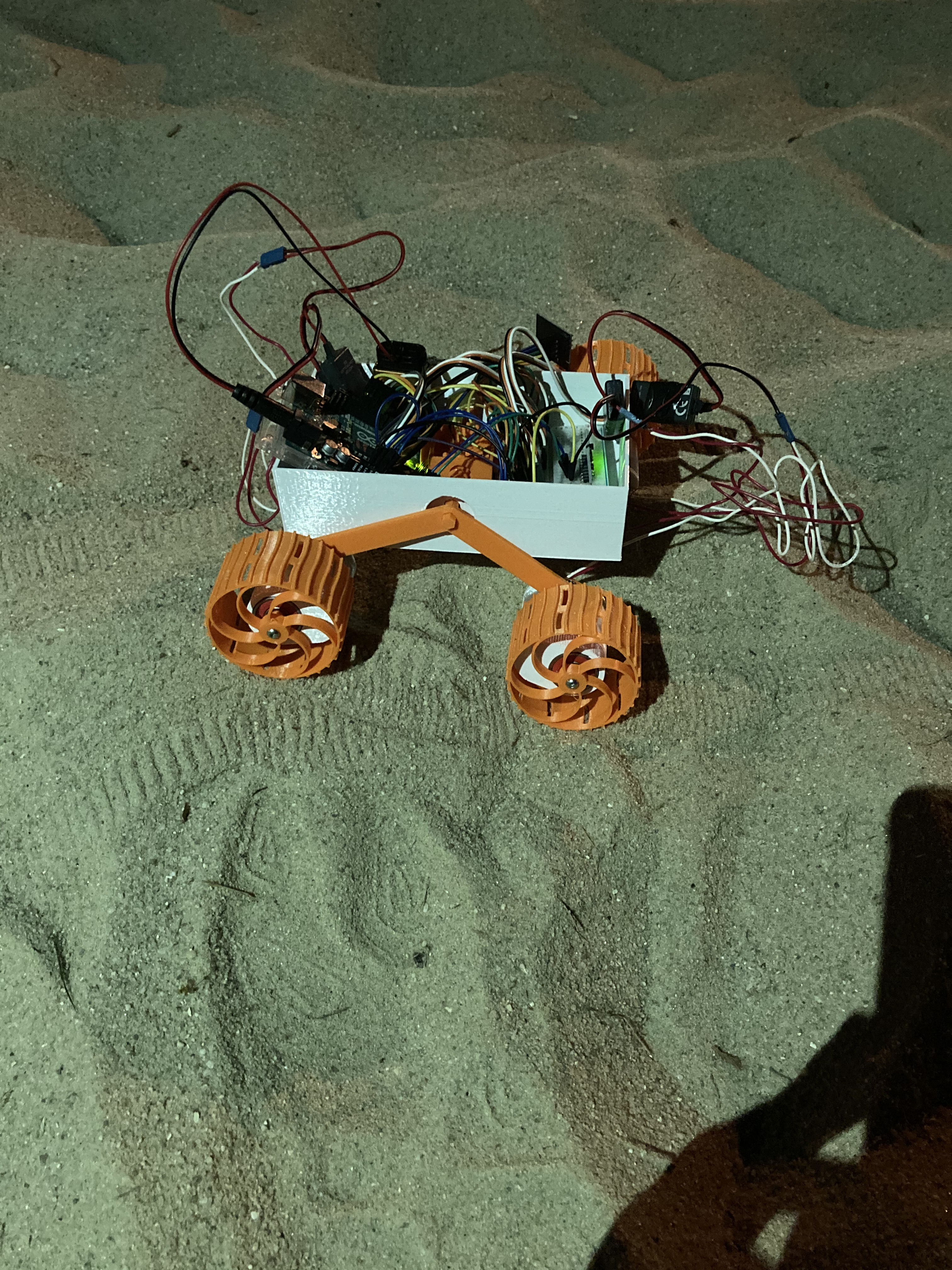

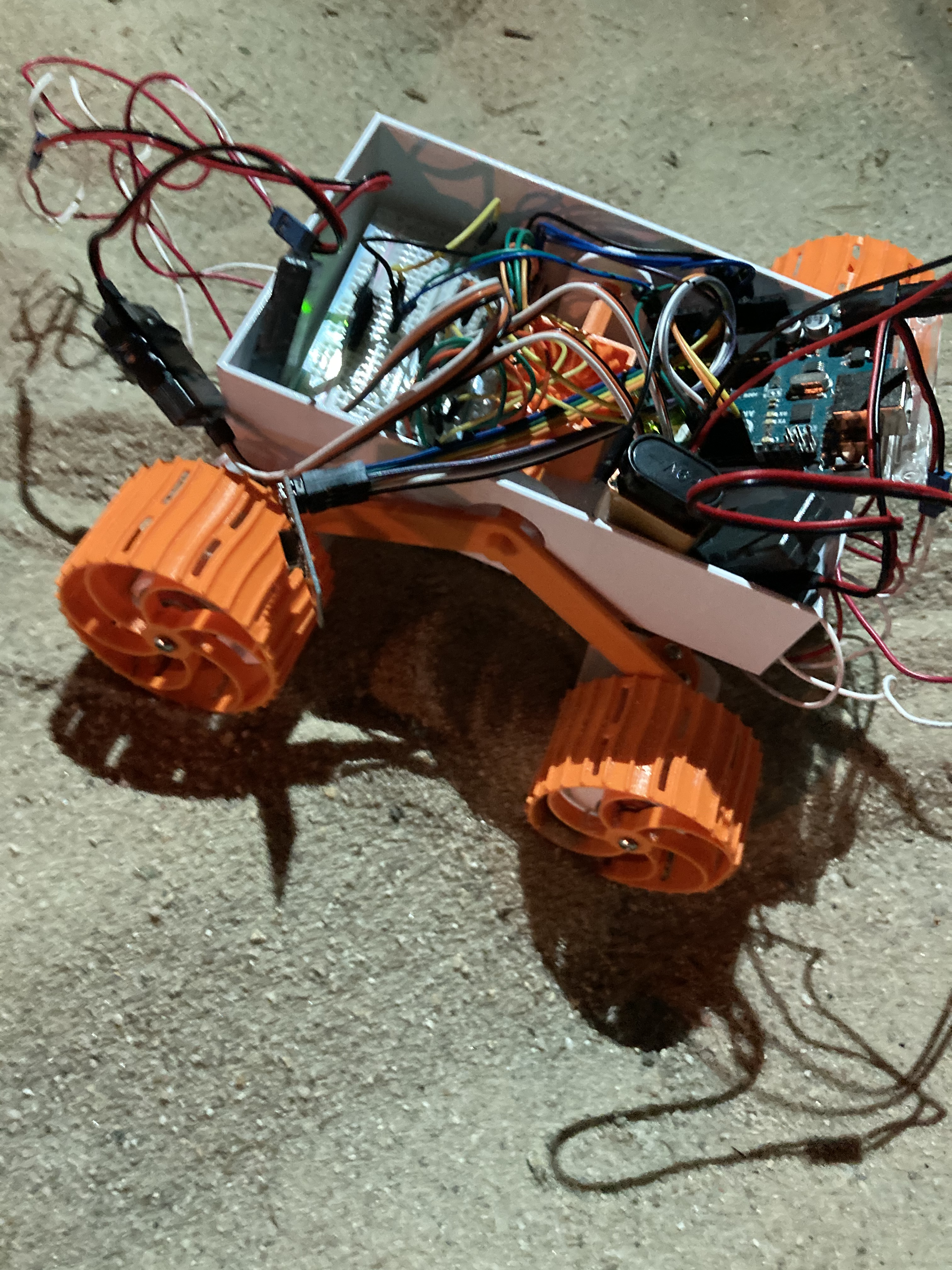

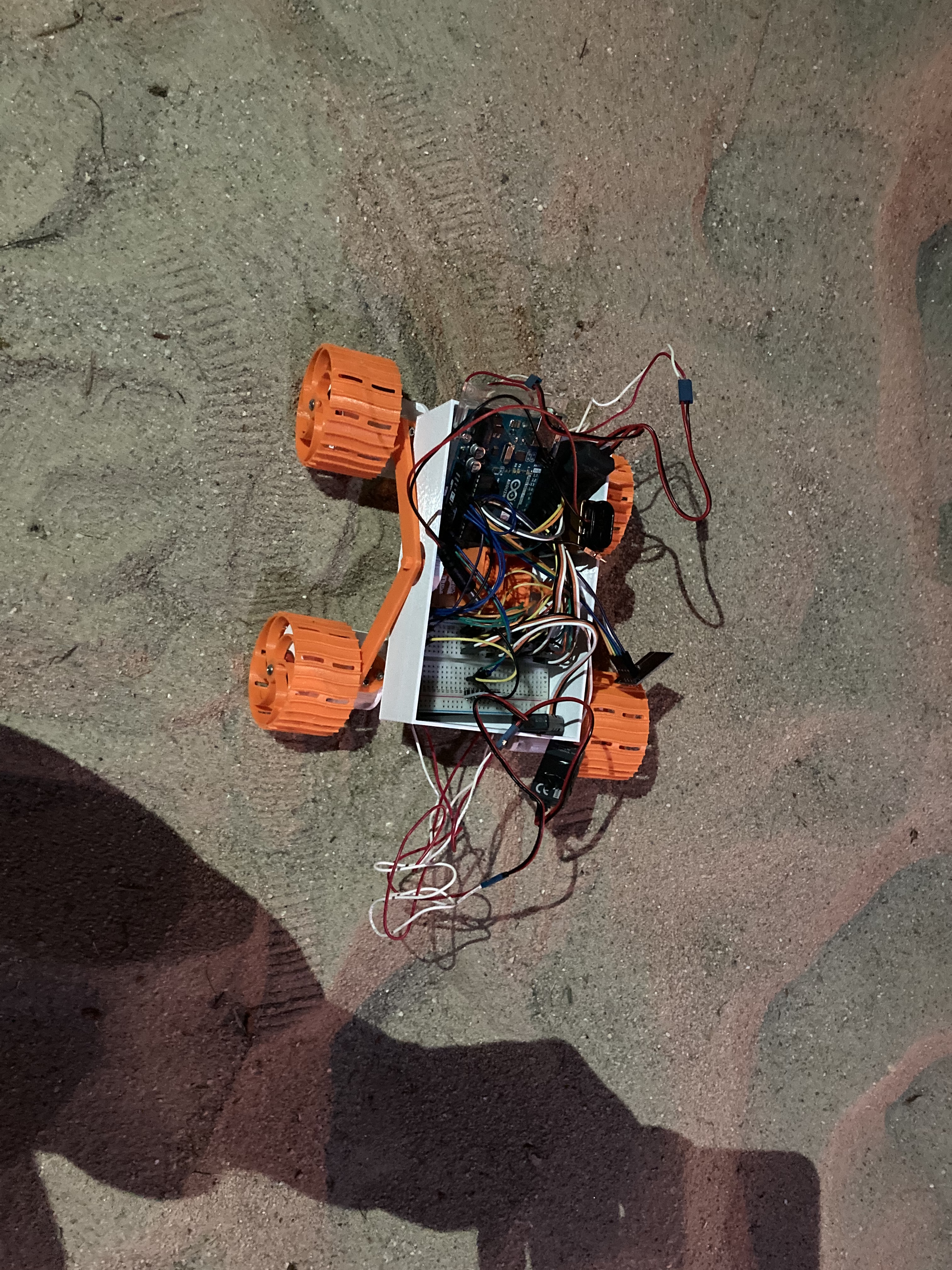

The final design worth discussing brought together the mechanical and software improvements I mentioned above. The wheels and motors on this design featured the electronics needed to create a feedback loop and the system itself was entirely wireless. The main limitation compared to my original vision was the use of four wheels rather than six. However, this was still good progress. The electronics system I used on this version was more or less identical to that of the earlier BEST robotics design, featuring the same controller. While the wheels featured the electronic hardware to create a control loop, it was not hooked up due to the Arduino Uno I was using running out of available pins. I would have invested in an Arduino Mega, but prices had not recovered from the chip shortage yet. Despite all this, the design was mature enough to take out to Drexel’s Buckley Green at 2 AM where the sand volleyball court would provide an excellent testing ground to see if my wheel designs would have enough traction to be functional. The design largely worked, but naturally left a lot of room for improvement.

This is where I had to leave this project due to my coursework picking up and not having nearly as much free time as I did before. I look forward to returning to this project as the amount of controls experience I have gained in the meantime will make it far more approachable. The microprocessor industry has also leaped forward in this time, and there may be a better alternative to the Arduinos I had been using available.